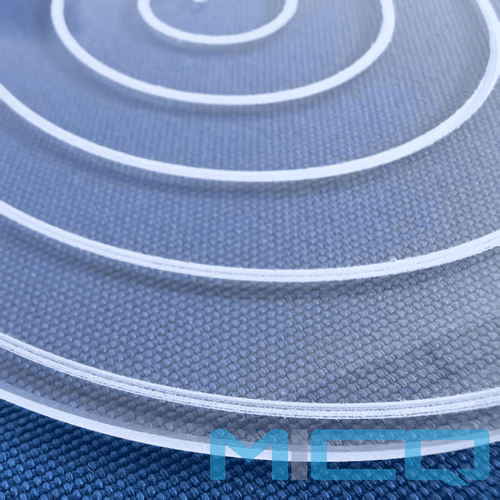

Type: CNC Engraving Spiral Thread Quartz Glass Disc

Material: High Fused Quartz(99.998% SiO2)

Packing: Wooden Case / Carton, Plastic Foam into Packing

Shipping: Free by Sea, Cheap Freight by Express to Door

Item NO.: 258417

MOQ: No limited

Custom Different type Available

CNC Engraving Spiral Thread Quartz Glass Disc

CNC Engraving Spiral Thread Quartz Glass Disc

CNC engraving of quartz spiral thread disc is a high-precision machining process that combines the precise control of numerical control (CNC) technology with the special properties of quartz materials. It is widely used in fields such as optics, semiconductors, and medical devices.

1. Material characteristics and pretreatment

Quartz characteristics: high hardness (Mohs 7), high brittleness, high temperature resistance, and need to avoid stress concentration that may cause cracking.

Preprocessing:

Annealing: eliminates internal stress and reduces the risk of cracking during processing.

Surface cleanliness: Ensure no dust or oil stains, avoid slipping or errors during carving.

2. Selection of CNC equipment

Machine type: high-precision CNC engraving machine or glass specific CNC, requirements:

Spindle speed ≥ 30000 RPM (high speed reduces edge cracking).

Positioning accuracy ≤ 0.005mm.

Cooling system: Water or air cooling is necessary to prevent thermal stress cracking.

Tool selection:

Diamond coated cutting tools: suitable for high hardness quartz.

Tip angle: A small angle (such as 60 °) is used for fine threading.

Tool diameter: Adjust according to the thread pitch (commonly 0.2-2mm).

3. Optimization of processing parameters

Cutting parameters:

Feed rate: 50-200 mm/min (low speed to reduce vibration).

Cutting depth: 0.01-0.1mm/time (layered processing).

Spindle speed: 20000-40000 RPM.

Coolant: Deionized water or specialized glass coolant to avoid impurity contamination.

4. Spiral thread programming

CAM software: Use ArtCAM, Mastercam, or specialized glass carving software.

Thread parameters:

Pitch: According to design requirements (such as 0.5-3mm).

Thread depth: usually 0.1-0.5mm (excessive depth can lead to brittle fracture).

Spiral angle: controlled by tool path (such as 30 ° -60 °).

Path planning:

Layered processing: gradually deepen to the target depth in 3-5 steps.

Down milling: Improve surface smoothness.

5. Clamping and positioning

Fixture design: vacuum adsorption table+soft gasket (such as silicone) to avoid local stress.

Alignment: The laser alignment instrument calibrates the Z-axis zero point with an error of ≤ 0.002mm.

6. Post processing

Polishing: Mild corrosion of hydrofluoric acid (HF) dilute solution to remove burrs (strict control of concentration and time is required).

Cleaning: Ultrasonic cleaning removes residual coolant and debris.

testing:

Optical profilometer: measures thread depth and pitch accuracy.

Microscopic examination: observe whether there are microcracks at the edges.

7. Common Problems and Solutions

Edge breakage: Reduce feed rate or replace worn tools.

Uneven thread: Check the radial runout of the spindle (should be ≤ 0.001mm).

Surface atomization: Adjust the coolant flow rate or switch to alcohol cooling.

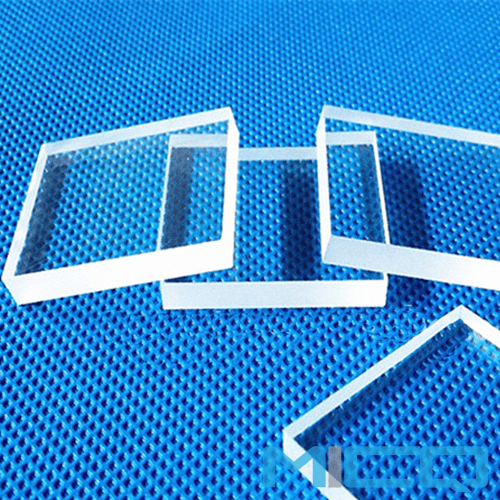

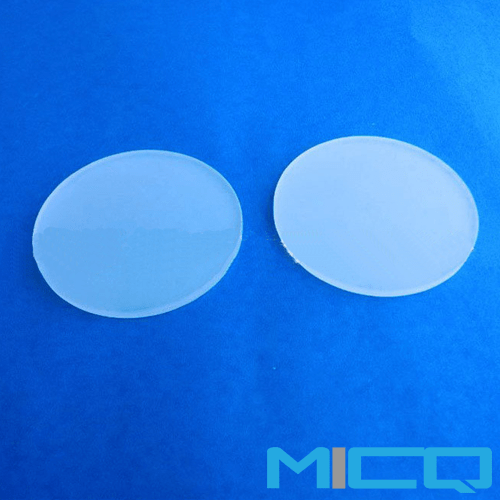

Fused Quartz Glass Features:

Fused quartz glass is a special industrial glass made of silicon dioxide. It is a very good basic material. Quartz glass has a series of excellent physical and chemical properties.

1. High temperature resistance. The softening point of fused quartz glass is about 1730℃ and can be used for long time working under 1100℃~1250℃. And working at 1450℃ in a short time.

2. Corrosion resistance. In addition to hydrofluoric acid, fused quartz glass is inert to other acids. Its acid resistance is 30 times as ceramic, 150 times as stainless steel. Especially, any other material cannot make a comparison with chemical stability of fused quartz at high temperature

3. The thermal stability is good. Thermal expansion coefficient is extremely small. And it can withstand severe temperature changes such that heating up to 1100℃ and putting it in normal temperature water will not crack.

4. The light transmittance is good. Quartz glass has good transmittance in the whole spectral band from ultraviolet to infrared. The transmittance of the visible light is above 95%. Especially in the ultraviolet spectrum band and the maximum transmittance is over 85%.

5. The electrical insulation performance is good. Resistance value of quartz glass equaling to 10000 times of ordinary glass. It is an excellent electrical insulating material and has good electrical properties even under high temperature.

As a leading China fused quartz glass supplier and manufacturer, we are providing best price as well as quality for all kinds of customized fused quartz products. We are also willing to look for long term partners who are a distributor or wholesaler specialized in fused quartz glass in local.

For prompt quotation, please contact us at below form.

LEAVE A MESSAGE

Fused quartz glasses have the excellent properties for their following features:

- High working temperature

- Thermal shock resistance

- High electrical insulation

- Optical transparency

- Chemical inertness