Quartz is a material characterized by exceptional physical and chemical stability. Its high purity, excellent thermal resistance, corrosion resistance, low thermal expansion coefficient, and superior optical properties render it an essential material in the pharmaceutical industry. Quartz instruments are extensively used across various pharmaceutical applications, including drug research and development, manufacturing processes, and quality control procedures. This discussion provides a comprehensive examination of the specific applications and significance of quartz instruments in the pharmaceutical sector from multiple perspectives.

- Drug research and synthesis

Chemical synthesis is a fundamental step in the drug development process. Quartz instruments are widely used in a variety of equipment due to their high chemical inertness, which allows them to withstand the corrosion of strong acids, strong alkalis and organic solvents. This makes them ideal for use in equipment such as reaction vessels, condensers and distillation devices. For instance, quartz reactors have been shown to maintain stability and prevent the introduction of impurities due to material corrosion in synthetic reactions carried out under high-temperature and high-pressure conditions. This ensures the accuracy of experimental data. Additionally, due to its high transparency, quartz vessels allows for direct observation of the reaction process, enabling researchers to monitor the status of the reaction in real time.

In the context of catalytic reactions, the use of quartz instruments is of particular importance due to their high purity. It is important to note that certain drug synthesis processes are extremely sensitive to metal ions. Ordinary glass or metal containers may release trace amounts of metal ions, which can interfere with the reaction process. Quartz instruments are characterized by their extremely low metal impurity levels, making them highly suitable for high-purity reactions. They are especially well-suited to the synthesis of special drugs such as chiral drugs and highly active compounds.

- Drug purification and separation

In the pharmaceutical industry, drug purification is a vital step in the process. Quartz instruments play a key role in this process, including distillation, extraction, and chromatographic separation. For example, molecular distillation is a technique used for the purification of high-boiling-point, heat-sensitive drugs. Quartz distillation equipment boasts high-temperature resistance and minimal thermal expansion, ensuring structural stability in extreme heat and protecting equipment from damage caused by temperature fluctuations.

Quartz capillaries are extensively utilized in analytical techniques such as high-performance liquid chromatography (HPLC) and gas chromatography (GC), owing to their chemical inertness and exceptional mechanical strength. These capillaries can withstand a variety of organic solvents and high-temperature conditions without adsorbing or reacting with the drugs being tested. This ensures the accuracy and reproducibility of the separation effect.

- Drug analysis and quality control

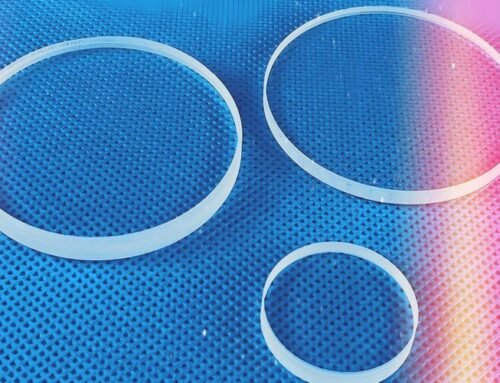

In the field of drug analysis, optical components such as quartz cuvettes and fluorescence cells are core parts of instruments like ultraviolet-visible spectrophotometers and fluorescence spectrometers. Optical components such as quartz cuvettes and fluorescence cells are essential components of analytical instruments such as ultraviolet-visible spectrophotometers and fluorescence spectrometers in the field of drug analysis. The high light transmittance and low fluorescence of quartz enable precise measurement of the light absorption or fluorescence intensity of drugs, facilitating its use in quality control processes such as content determination and impurity analysis.

- Biological pharmacyand genetic engineering

In the domain of biological pharmaceuticals, quartz instruments also assume a significant role. For instance, in the context of polymerase chain reaction (PCR), the utilization of quartz PCR tubes or microfluidic chips has been demonstrated to augment amplification efficiency and precision, attributable to their low adsorption and high thermal conductivity.

Moreover, quartz fibre filters are utilized for the filtration or purification of biological macromolecules, including proteins and nucleic acids. It has been demonstrated that their high chemical stability can serve to prevent loss or contamination of samples. In the context of cell culture or gene editing experiments, quartz culture dishes or microcarriers have been utilized for the cultivation of specific cell types or the investigation of gene delivery systems, owing to their biocompatibility and low toxicity.

- Packaging and storage

Despite the relatively high cost of quartz materials, they are still utilized in the packaging of certain pharmaceutical products. For instance, high-purity quartz ampoules can be used to store injections or vaccines that are sensitive to light and heat. The excellent barrier properties of these materials have the potential to extend the shelf life of drugs.

- Summary

The application of quartz instruments in the pharmaceutical industry spans the entire spectrum from research and development to manufacturing. Their high purity, corrosion resistance, thermal stability, and superior optical properties render them an ideal choice for numerous critical processes. Although the production cost of quartz instruments is relatively high, their contribution to ensuring drug quality and enhancing manufacturing efficiency remains unparalleled. With the ongoing advancement of pharmaceutical technologies, the utilization of quartz instruments is expected to expand further, offering increasingly reliable support for drug development and production operations.