Quartz glass is a special industrial technology material with a single component of silicon dioxide, exhibiting exceptional physical and chemical properties. Its comprehensive characteristics are unparalleled among all types of glass, earning it the title of the “king of glass.” In the semiconductor industry, quartz glass is extensively utilized due to its remarkable attributes, including high purity, excellent high temperature resistance, low thermal expansion, and strong chemical stability.

The integrated circuit industry chain can be broadly categorized into three primary segments: circuit design, chip manufacturing, and packaging and testing. Within this framework, the processing of semiconductor products primarily encompasses two critical phases: chip manufacturing (Front End) and packaging&testing (Back End). The production process for chip manufacturing is intricate, involving numerous steps that require a variety of auxiliary quartz glass devices. Consequently, high-purity quartz material emerges as a vital auxiliary consumable that is extensively utilized throughout the semiconductor IC chip manufacturing process.

In the process of manufacturing silicon wafers, a significant quantity of quartz glass products are utilized for the production of quartz crucibles used as wafer IC carriers (pulled single crystals). Additionally, some quartz cleaning containers are also used. The quartz crucible is manufactured from high-purity quartz sand.

The manufacturing process of a silicon wafer includes a series of processing stages, including oxidation, epitaxy, photothetching, etching, diffusion, CVD, ion implantation, and grinding. Among these stages, quartz glass, renowned for its high purity, high temperature resistance, low thermal expansion, corrosion resistance, and other exceptional properties, is a widely utilized material.

In the process of diffusion and oxidation, the following devices are employed with great frequency: quartz glass diffusion tubes and quartz flanges matched to the diffusion tubes; quartz glass furnace tubes (which facilitate the transfer of quartz boats into or out of the diffusion furnace); quartz boats (which serve to carry silicon wafers), and holders (which support and carry multiple quartz boats).

The quartz glass diffusion tube represents one of the most significant and extensively utilized quartz glass products within the semiconductor industry. Its purity, high temperature deformation resistance and geometric size have a direct impact on the quality, cost and production efficiency of integrated circuits and devices.

The quartz glass boat and holder are essential equipment for the diffusion, oxidation, CVD deposition and annealing treatment of single crystalline silicon. While the specifications and dimensions of quartz boats may vary considerably, they are primarily classified into two categories: horizontal boats and vertical boats. The quartz boat and holder are in direct contact with the single crystalline silicon wafer at elevated temperatures, necessitating the utilization of quartz glass that exhibit exceptional purity, high temperature resistance, and dimensional accuracy.

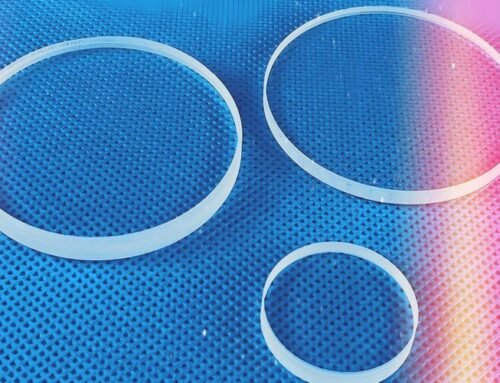

The etching of integrated circuits necessitates the utilization of corrosion resistant quartz glass materials and products. Therefore, a considerable quantity of quartz materials are used in the etching process. The main products include quartz rings, quartz glass reaction chambers and sample holders. Furthermore, quartz glass materials with high chemical stability are required for the processing of silicon wafers pickling and ultrasonic cleaning. The main products include quartz glass flower baskets (for use in silicon wafer pickling and ultrasonic cleaning), cleaning tanks (for the carrier of washing liquid), quartz bell jars (for use in wafer epitaxy), etc.

The main substrate material of the photomask plate used in semiconductor chip photolithography is also quartz glass. Because the photomask plate is a high-precision tool employed in the transfer of graphic “negative film” in the production of liquid crystal displays and semiconductors, it determines the accuracy and quality of the resulting electronic components, and therefore the quartz glass material used in the photomask plate must meet exacting standards. The quartz glass substrate of the photomask plate typically necessitates the utilization of high-purity synthetic quartz ingots as the fundamental materials.