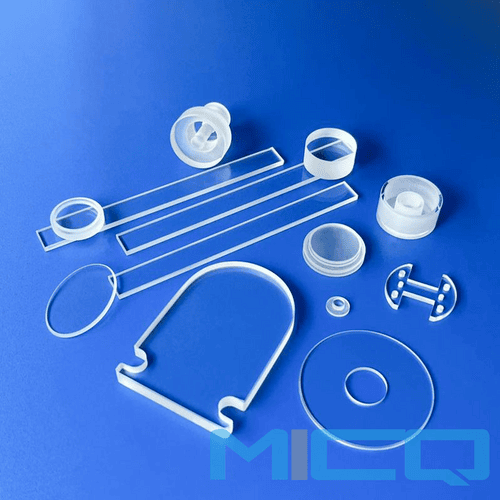

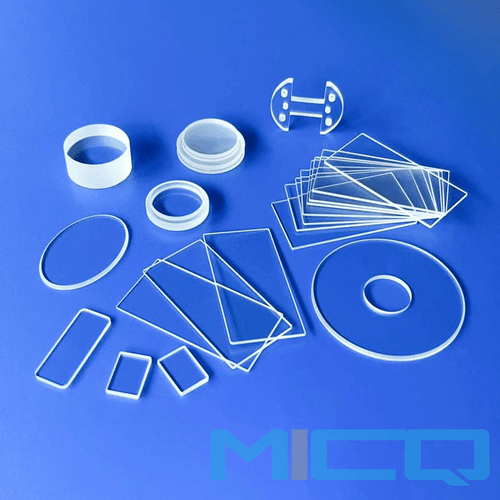

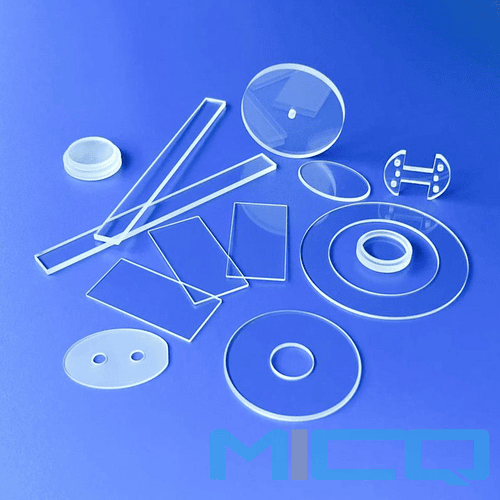

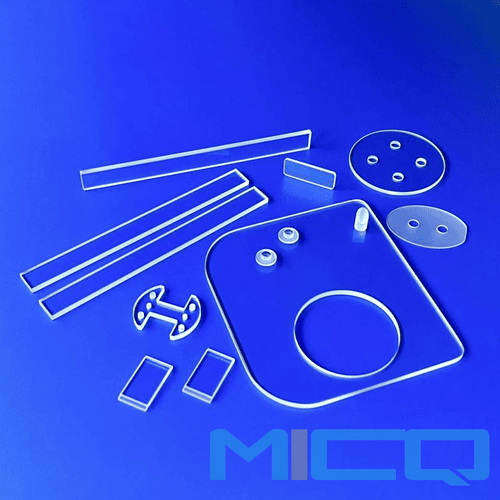

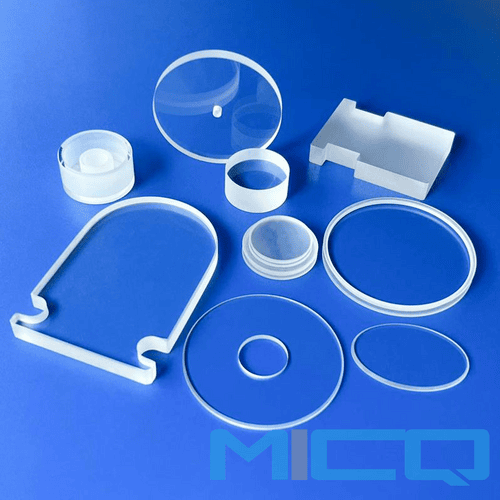

Type: Custom Fabrication of Quartz Glass Gaskets in Varies

Material: High Fused Quartz(99.998% SiO2)

Packing: Wooden Case / Carton, Plastic Foam into Packing

Shipping: Free by Sea, Cheap Freight by Express to Door

Item NO.: 258181

MOQ: No limited

Custom Different type Available

Custom Fabrication of Quartz Glass Gaskets in Varies

Custom Fabrication of Quartz Glass Gaskets in Varies

Quartz glass gasket is a precision component made of high-purity silicon dioxide (SiO ₂), which has excellent high temperature resistance, chemical stability, and low thermal expansion coefficient. It is widely used in semiconductor, optical, vacuum, and high-temperature industrial fields. The production method of quartz glass gasket requires high precision and strict process control.

1. Material selection of quartz glass gasket

Use high-purity quartz glass (SiO ₂ content ≥ 99.9%) to ensure low thermal expansion coefficient, high temperature resistance (softening point of about 1700 ℃), and good chemical stability.

Common types: transparent or opaque quartz glass, choose according to your needs (such as JGS1 synthetic quartz glass for UV transmission).

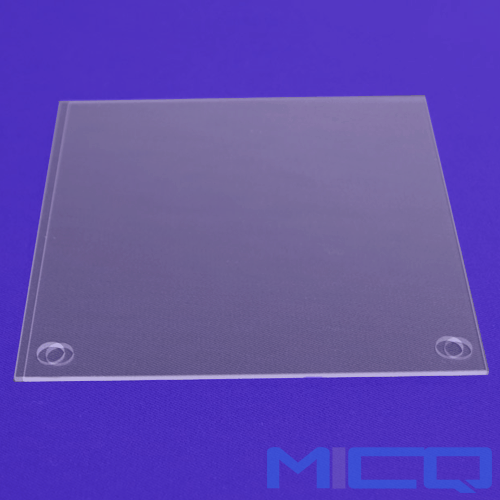

2. Cut and shape quartz glass gasket

A. Tool selection:

Diamond saw blade or laser cutting machine (high precision, minimal edge damage).

Water jet cutting (suitable for thicker plates to avoid thermal stress).

B. Steps:

Cut the quartz glass sheet into approximate sizes (leaving machining allowance) according to the design drawings.

Remove edge burrs after cutting (lightly corrode with hydrofluoric acid or mechanically grind).

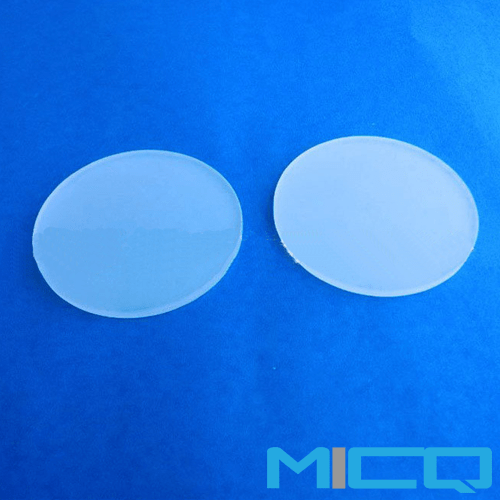

3. Precision machining of quartz glass gaskets

A. Grinding and polishing:

Rough grinding: Use boron carbide or diamond abrasive to grind the thickness of the gasket to near the target size (leaving a margin of 0.1-0.2mm).

Fine grinding: Use finer abrasives (such as alumina or ceria) to improve surface smoothness.

Polishing: Use asphalt polishing mold and cerium oxide slurry to achieve an optical grade surface (Ra<0.5nm).

Equipment: Double sided grinder or single-sided polishing machine (ensuring parallelism ≤ 0.005mm).

B. Thickness control:

Real time monitoring using a micrometer or laser thickness gauge, with tolerances typically controlled within ± 0.01mm.

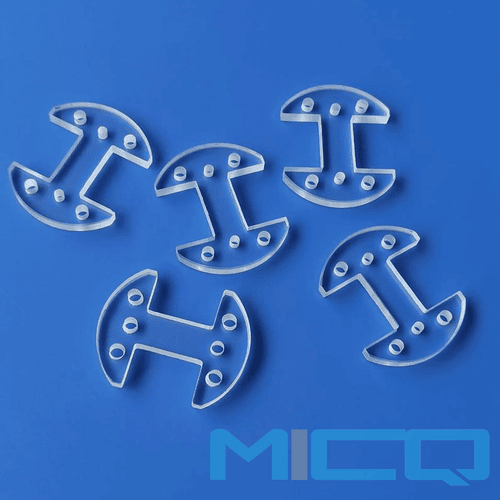

4. Drilling and shape processing of quartz glass gasket

A. Ultrasonic drilling (small aperture) or laser drilling (high precision, no cracks).

Chamfering is required after drilling to prevent stress concentration.

B. CNC engraving machine processes complex shapes, or photolithography+etching process (micrometer level precision).

5. Cleaning and testing of quartz glass gaskets

A. Cleaning process:

Deionized water ultrasonic cleaning (to remove particles).

Acid washing (hydrofluoric acid: nitric acid=1:10, removing surface impurities).

Plasma cleaning (to improve surface cleanliness).

B. Quality inspection:

Dimensional accuracy: Three coordinate measuring instrument.

Surface quality: White light interferometer or atomic force microscope (AFM).

Stress detection: Polarimeter (to ensure no residual stress).

6. Annealing treatment of quartz glass gasket (optional)

Purpose: To eliminate processing stress and improve stability.

workmanship

Keep at 1100-1200 ℃ for 2-4 hours and slowly cool down (rate ≤ 5 ℃/minute).

7. Coating of quartz glass gasket (according to requirements)

Common coatings:

Anti reflective film (such as MgF ₂, used for optical applications).

Metallic coating (such as Cr/Au, used for electrode contact).

8. Application scenarios of quartz glass gaskets:

Semiconductor equipment (wafer carrier, etching chamber).

Optical system (lens pad, laser window).

High temperature environment (thermocouple insulation, vacuum sealing).

Through the above process, quartz glass gaskets can meet the requirements of high precision and extreme environmental resistance. According to different usage environments, JGS1, JGS2, or JGS3 can be selected as processing materials.

Fused Quartz Glass Features:

Fused quartz glass is a special industrial glass made of silicon dioxide. It is a very good basic material. Quartz glass has a series of excellent physical and chemical properties.

1. High temperature resistance. The softening point of fused quartz glass is about 1730℃ and can be used for long time working under 1100℃~1250℃. And working at 1450℃ in a short time.

2. Corrosion resistance. In addition to hydrofluoric acid, fused quartz glass is inert to other acids. Its acid resistance is 30 times as ceramic, 150 times as stainless steel. Especially, any other material cannot make a comparison with chemical stability of fused quartz at high temperature

3. The thermal stability is good. Thermal expansion coefficient is extremely small. And it can withstand severe temperature changes such that heating up to 1100℃ and putting it in normal temperature water will not crack.

4. The light transmittance is good. Quartz glass has good transmittance in the whole spectral band from ultraviolet to infrared. The transmittance of the visible light is above 95%. Especially in the ultraviolet spectrum band and the maximum transmittance is over 85%.

5. The electrical insulation performance is good. Resistance value of quartz glass equaling to 10000 times of ordinary glass. It is an excellent electrical insulating material and has good electrical properties even under high temperature.

As a leading China fused quartz glass supplier and manufacturer, we are providing best price as well as quality for all kinds of customized fused quartz products. We are also willing to look for long term partners who are a distributor or wholesaler specialized in fused quartz glass in local.

For prompt quotation, please contact us at below form.

LEAVE A MESSAGE

Fused quartz glasses have the excellent properties for their following features:

- High working temperature

- Thermal shock resistance

- High electrical insulation

- Optical transparency

- Chemical inertness