The transmittance of fused quartz tube is basically the same as that of optical quartz plate. The biggest difference is what way to produce out its optical properties. Quartz tubing has formed a specific transparency when it comes out of the furnace, and quartz glass plate reach its optical properties through a series of subsequent processing. Therefore, the optical properties of quartz plate can form different optical levels according to the different way of processing.

The design purpose of quartz tube is mainly to meet the optical characteristics of ultraviolet lamp. If it is used as a lampshade, its finish can usually reach 60 / 40. In this way, the sterilization effect can be effectively achieved.

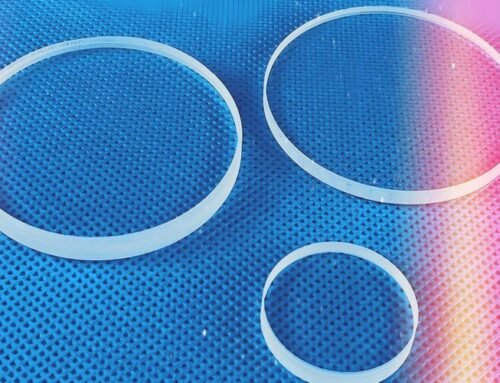

In the process of deep processing of quartz tube, scratches or collapse points are often left on the surface of quartz tubing. At this time, we will fire quartz tube as a whole to restore the completely transparent state of the surface again. But this will still have a little impact on the light transmittance of the surface. Therefore, when using quartz tubes to produce quartz glass products for optical purposes, we still try our best to reduce surface scratches or damage to avoid repairing it again.