Quartz instruments, renowned for their exceptional properties, including high purity, excellent thermal stability, resistance to high temperatures and corrosion, and superior optical transmittance, are extensively utilized in material preparation, characterization, and analytical processes. With the rapid advancement of materials science, the demand for precise experimental conditions and accurate measurement techniques has grown significantly, further highlighting the critical role of quartz instruments. This article presents a systematic examination of the diverse applications of quartz instruments in materials science research, along with an in-depth analysis of their inherent advantages.

- The application of quartz instruments in material preparation

- Synthesis of high-temperature materials

Quartz tube furnaces and quartz crucibles are essential equipment in the production processes of high-temperature ceramics, semiconductor materials, and superconducting materials. For instance, quartz reaction tubes are used in the preparation of semiconductor materials by chemical vapor deposition (CVD). These tubes can withstand high-temperature environments in excess of 1000 °C while maintaining chemical stability and preventing the introduction of impurities. In the process of synthesizing new ceramic materials through high-temperature solid-state reactions, quartz crucibles are used to ensure that no side reactions occur with reactants, thereby guaranteeing the purity of the products.

- Crystal growth

Quartz instruments are extensively utilized in the domain of single crystal growth, particularly in the context of silicon single crystal fabrication by the Czochralski method. High-purity quartz crucibles are regarded as the prevailing standard for containers in this field. The high-temperature resistance and chemical inertness of quartz are essential for the purity of molten silicon. Its coefficient of thermal expansion is comparable to that of silicon, thereby minimizing crystal defects arising from thermal stress. Moreover, quartz high-pressure reactors frequently serve as the primary apparatus in the hydrothermal synthesis of nanomaterials, zeolite molecular sieves, and analogous materials, as they can resist high temperatures and pressures without compromising the integrity of the reaction system.

- Film preparation

In thin film preparation techniques such as physical vapour deposition (PVD) and atomic layer deposition (ALD), quartz substrates represent a popular choice due to their exceptional surface flatness and reliable thermal stability. In the process of manufacturing transparent conductive oxide (such as ITO) films, the low coefficient of thermal expansion of quartz substrates has been shown to have a beneficial effect on the reduction of film stress and the enhancement of the quality of the films. Quartz bell jars are also frequently used in vacuum coating systems, due to their light transmittance, which facilitates real-time observation of the deposition process.

- The application of quartz instruments in material characterization

- Spectral analysis

The core component of a UV visible spectrophotometer generally adopts a quartz cuvette due to its high light transmittance in the ultraviolet region (whereas ordinary glass strongly absorbs ultraviolet light). When conducting analyses using fluorescence spectroscopy, Raman spectroscopy and other methods, quartz sample cells are essential for ensuring the accurate collection of full-band signals. When conducting infrared spectroscopy analysis, high-purity quartz windows are able to prevent themselves from absorbing and interfering sample signals.

- Thermal analysis technology

It is common practice to equip differential scanning calorimeters (DSC) and thermal gravimetric analyzers (TGA) with quartz sample dishes. The key benefits of quartz in this respect include its ability to resist high temperatures, its non-reactivity with samples, and its consistent thermal conductivity. Quartz microbalances are ideal for the study of surface adsorption of thin film materials due to their high sensitivity and stability, and their ability to accurately measure nanogram-level mass changes.

- Microscopic examination

In a high-temperature microscope system, the quartz observation window is capable of withstanding extreme temperature environments, thus enabling in-situ observation of materials at high temperatures. The quartz sealing component of the environmental scanning electron microscope (ESEM) is capable of maintaining a specific atmosphere in the sample chamber while ensuring the penetration of the electron beam.

- The unique value of quartz instruments in the research of special materials

- Research on optical materials

Quartz is an ideal optical window material. In the field of laser material and nonlinear optical crystal research, quartz components, including lenses and prisms, do not cause additional absorption or scattering. In the research and development of optical fibre materials, quartz sleeve tubes are used to protect sensitive optical fibre preform rods. Their refractive index matching characteristics reduce the loss of optical signals.

- Research on semiconductor materials

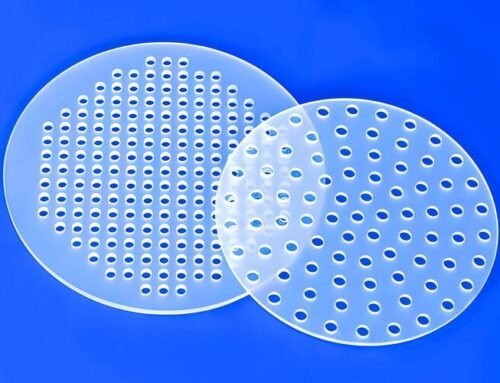

Ultra-high purity quartz products are considered fundamental materials in the semiconductor industry. In the course of processes such as silicon wafer cleaning, etching, and diffusion, quartz basket and quartz boat components can serve to prevent metal contamination. In the molecular beam epitaxy (MBE) system, the quartz observation window can monitor the epitaxial growth process in real time without interfering with the ultra-high vacuum environment.

From fundamental research to industrial applications, the high purity, thermal stability, and superior optical properties of quartz products meet the increasingly stringent demands of modern materials science. With ongoing advancements in processing technologies and the emergence of novel materials, quartz instruments are expected to continue providing robust support for innovation in materials research, demonstrating significant potential in cutting-edge fields such as new functional materials, low-dimensional materials, and materials under extreme conditions.