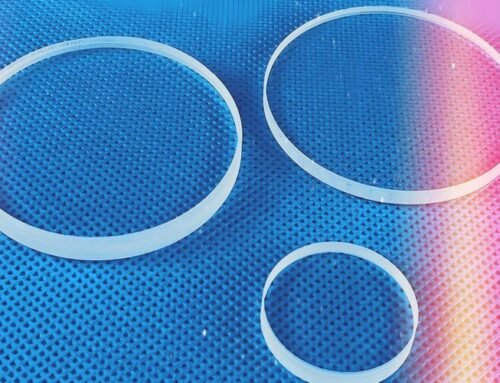

In the processing of quartz tubes, optimizing the rate of material utilization is a key objective. This will reduce production costs and minimize resource waste, enhancing economic and environmental benefits. Quartz tubes are renowned materials due to their high levels of purity and efficiency, making them a popular choice in fields such as semiconductors, optics and photovoltaics. However, their processing can be challenging and their cost is relatively high. It is therefore vital to optimize the material utilization rate through the implementation of scientific and rational methodologies. The following explores how to achieve this goal from multiple perspectives.

- Optimize the design and cutting process

The initial phase in the processing of quartz tubes involves the design and cutting stages. Optimal design is pivotal to enhancing the utilization rate of materials. Prior to processing, the dimensions of the quartz tube should be precisely calculated in accordance with the specific requirements, ensuring that any surplus material is minimized. Meanwhile, the adoption of advanced cutting technology can effectively reduce material waste.

- Effectivemanagement of the processing flow

During the processing of quartz tubes, effective management of the processing flow can enhance material utilization. Specific measures include the centralized processing of quartz tubes of the same specification to reduce both equipment adjustment time and material waste. Another measure is adjusting the sequence of processing in a logical and consistent manner, taking into account the dimensions and configuration of the quartz tube. Large-sized or complex-shaped components should be prioritized, with the remaining material then being used for small-sized or simple-shaped components.

- Improve processing accuracy

The processing accuracy of quartz tubes directly impacts the utilization rate of materials. Insufficient processing accuracy can result in a higher scrap rate and increased material waste. Consequently, enhancing processing accuracy is a pivotal strategy to optimize material utilization. In order to ensure that dimensional errors are minimized during the processing, it is recommended that high-precision processing equipment, such as high-precision CNC machine tools and grinders, are selected.

- Adopt advanced processing technology

Advances in technology have led to the development of sophisticated processing techniques that can significantly enhance the utilization rate of quartz tubes. For instance, the use of ultrasonic processing is applicable to the precise grinding of quartz tubes and can achieve high levels of precision and minimal energy loss. Chemical mechanical polishing technology is an effective solution for removing minor surface imperfections on quartz tubes. It enhances surface quality and reduces the scrap rate caused by surface defects.

- Strengthen quality control

In the processing of quartz tubes, effective quality control is essential for enhancing the utilization rate of materials. It is imperative to strictly control the quality of raw materials in order to avoid processing failures and material wastage caused by defects in the raw materials. Real-time monitoring of the processing procedure is essential for the timely identification and correction of any issues, thereby reducing the scrap rate. Furthermore, it is crucial to establish a comprehensive quality management system that strictly controls every stage of the process, from design to finished product inspection, in order to ensure the quality of the quartz tubes.

In the processing of quartz tubes, improving material utilization requires coordinated efforts across multiple areas, including design, manufacturing, and quality control. By implementing advanced technologies, refining manufacturing processes, enhancing precision, and strengthening quality management, it is possible to effectively minimize material waste, reduce production costs, and enhance economic efficiency. Furthermore, this approach aligns with the principles of sustainable development, contributing to lower resource consumption and reduced environmental impact. As technology continues to advance, the material utilization rate in quartz tube processing is expected to rise further, thereby providing stronger support for the growth of related industries.