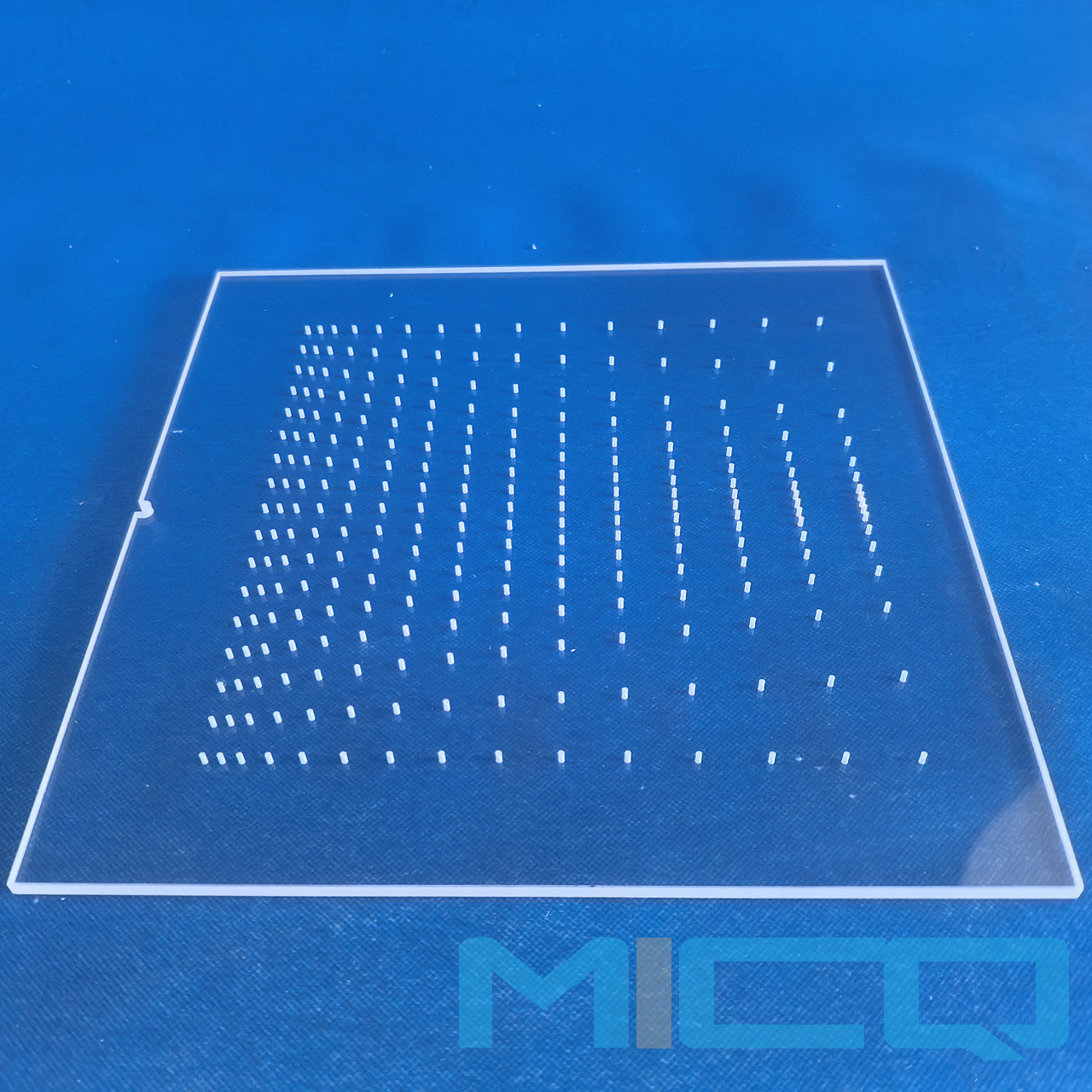

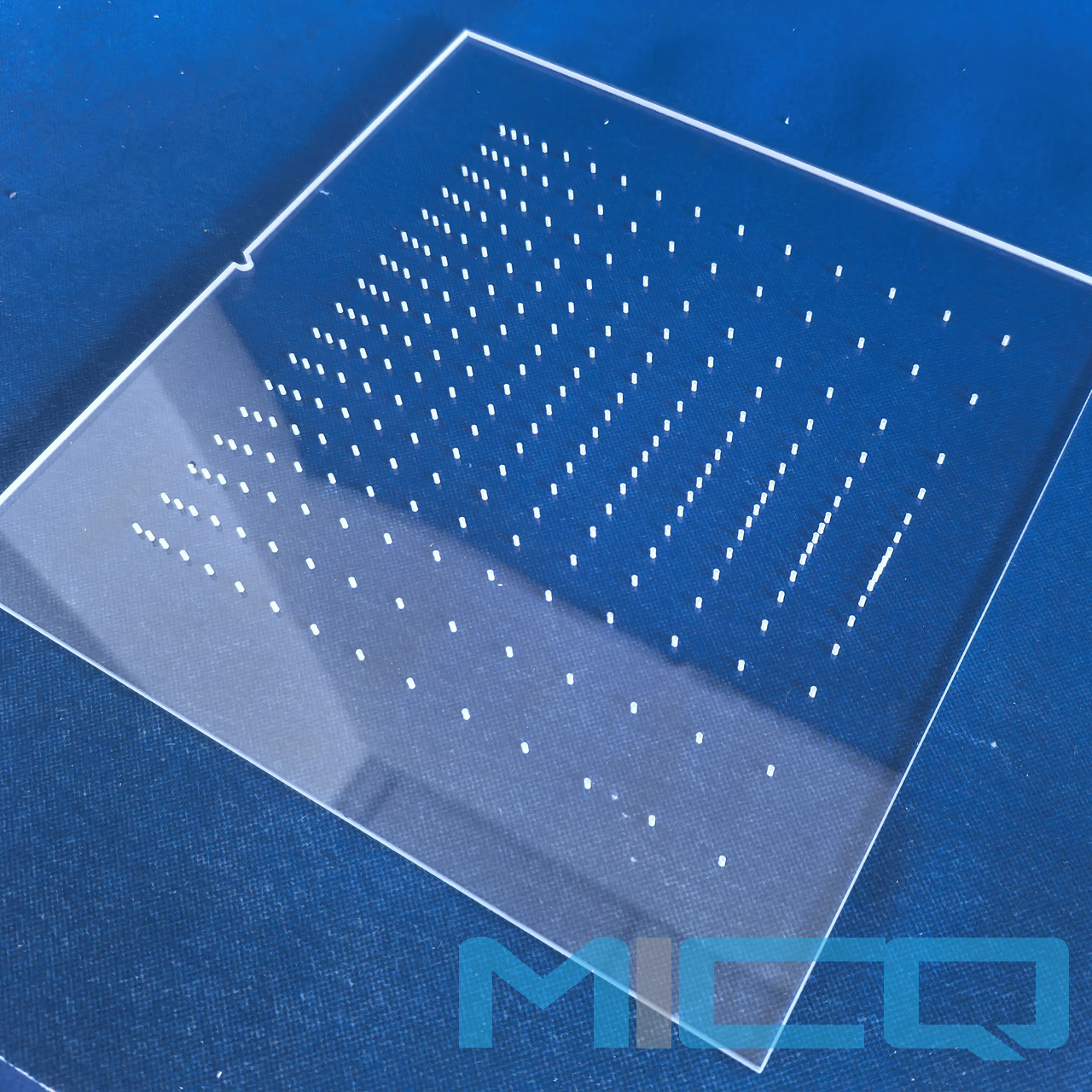

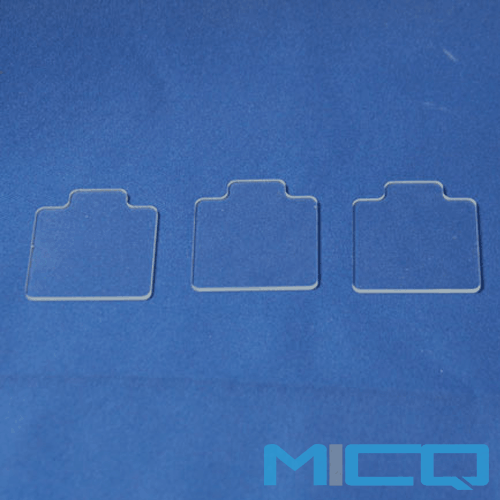

Type: Custom Fabrication Laser Drilling Microporous Fused Quartz Plate

Material: High Fused Quartz(99.998% SiO2)

Packing: Wooden Case / Carton, Plastic Foam into Packing

Shipping: Free by Sea, Cheap Freight by Express to Door

Item NO.: 255261940

MOQ: No limited

Custom Different type Available

Custom Fabrication Laser Drilling Microporous Fused Quartz Plate

Custom Fabrication Laser Drilling Microporous Fused Quartz Plate

Laser drilling of microporous quartz glass plates is a high-precision processing technology that involves multiple aspects such as material properties, laser parameter optimization, and process control. The following is a detailed answer to this requirement:

1. Characteristics and processing difficulties of quartz glass

High hardness and brittleness: Quartz glass (SiO ₂) has high hardness (Mohs 7), high brittleness, and traditional mechanical processing is prone to cracking or edge collapse.

High melting point (~1700 ℃): High energy density lasers are required to melt or vaporize materials.

Transmittance : High transmittance for visible light and near-infrared light (such as 1064 nm), it is necessary to choose a laser with an appropriate wavelength to improve absorption.

2. Laser type selection**

(1) UV Laser

Wavelength: 355 nm or 266 nm (shorter wavelengths are more easily absorbed).

Advantages: Small heat affected zone, suitable for precision micro hole machining (pore size can be as low as micrometers).

Application scenarios: optical devices, sensor micropores, microfluidic chips.

(2) Ultrafast laser (femtosecond/picosecond laser)

Pulse width * *: femtosecond (10 ⁻¹⁵ seconds) or picosecond (10 ⁻¹² seconds).

Advantages: Extremely low thermal effect, almost no melting residue, smooth pore wall.

Application scenarios: high-precision optical components, semiconductor packaging.

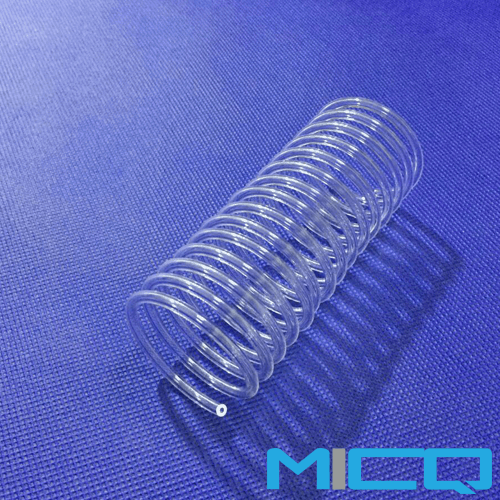

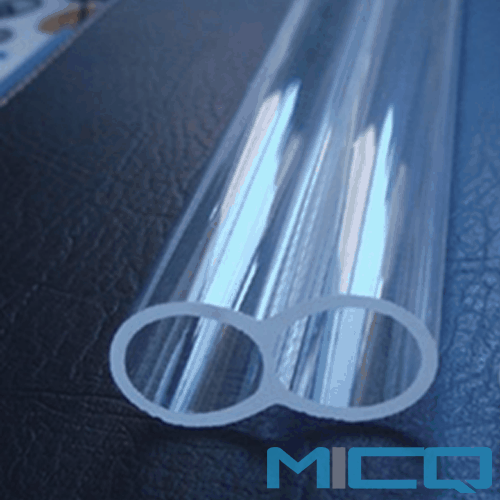

Fused Quartz Glass Features:

Fused quartz glass is a special industrial glass made of silicon dioxide. It is a very good basic material. Quartz glass has a series of excellent physical and chemical properties.

1. High temperature resistance. The softening point of fused quartz glass is about 1730℃ and can be used for long time working under 1100℃~1250℃. And working at 1450℃ in a short time.

2. Corrosion resistance. In addition to hydrofluoric acid, fused quartz glass is inert to other acids. Its acid resistance is 30 times as ceramic, 150 times as stainless steel. Especially, any other material cannot make a comparison with chemical stability of fused quartz at high temperature

3. The thermal stability is good. Thermal expansion coefficient is extremely small. And it can withstand severe temperature changes such that heating up to 1100℃ and putting it in normal temperature water will not crack.

4. The light transmittance is good. Quartz glass has good transmittance in the whole spectral band from ultraviolet to infrared. The transmittance of the visible light is above 95%. Especially in the ultraviolet spectrum band and the maximum transmittance is over 85%.

5. The electrical insulation performance is good. Resistance value of quartz glass equaling to 10000 times of ordinary glass. It is an excellent electrical insulating material and has good electrical properties even under high temperature.

As a leading China fused quartz glass supplier and manufacturer, we are providing best price as well as quality for all kinds of customized fused quartz products. We are also willing to look for long term partners who are a distributor or wholesaler specialized in fused quartz glass in local.

For prompt quotation, please contact us at below form.

LEAVE A MESSAGE

Fused quartz glasses have the excellent properties for their following features:

- High working temperature

- Thermal shock resistance

- High electrical insulation

- Optical transparency

- Chemical inertness