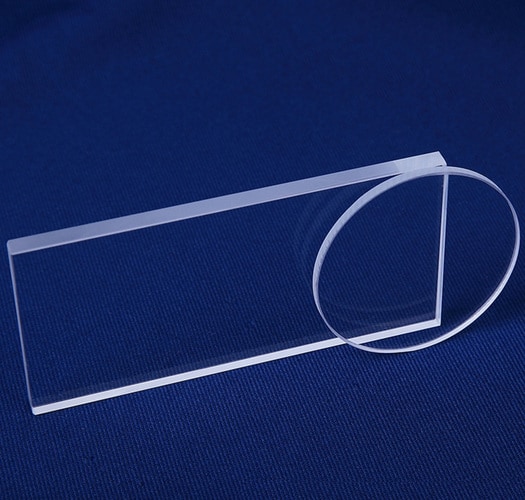

Optical Quartz Glass Parameters

| Surface Features | Surface Roughness (Ra)(um) Value | Processing Method |

|---|---|---|

| Obvious Scratches | Ra100, Ra50, Ra25 | Rough Grinding & Rough Plane |

| Tiny Scratches | Ra12.5, Ra6.3, Ra3.2 | Rough Grinding & Fine Grinding |

| Invisible Scratches, Extremely Subtle processing ripples | Ra1.6, Ra0.8, Ra0.4 | Fine Grinding & Abrading |

| Mirror Surface, Optical Grade | Ra0.2, Ra0.1, Ra0.05 | Abrading & Optical Polishing |

The polishing grade of quartz glass is usually represented by two parameters: Surface Finish (smoothness of the surface–30 / 20, 60 / 40, 80 / 50) and Surface Roughness (RA)

-

The higher value of surface finish, the smoother surface. This is a special representation of the old standard, which is no longer used.

-

The smaller value of surface roughness, the smoother surface. This is the expression method of national standards and international standards currently.