Quartz boats play a critical role in the semiconductor industry and are among the essential materials used in semiconductor manufacturing. Their unique physical and chemical properties enable high performance in processes requiring high temperatures, extreme purity, and precise control. As such, quartz boats are widely utilized in key fabrication steps, including wafer processing, thin film deposition, etching, and cleaning.

- The applications of quartz boats in semiconductor industry

- Wafer carrying and transmission

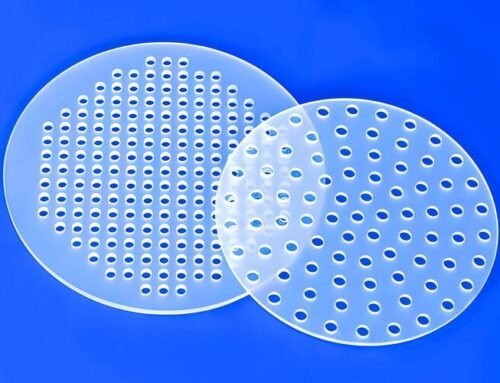

In the semiconductor manufacturing process, it is necessary to transfer wafers between different processing equipment. The use of quartz boats, as the carriers of wafers, can ensure their stability during transportation and prevent damage caused by vibration or friction. Furthermore, the design of quartz boats is generally capable of accommodating multiple wafers, thus enhancing production efficiency.

- High-temperature process

In the field of semiconductor manufacturing, numerous critical processes are conducted in high-temperature environments, including diffusion, oxidation, and annealing. Quartz boats are the ideal carriers for these processes due to their high-temperature resistance and thermal stability. It can be used for extended periods at high temperatures without deformation or damage, thereby ensuring the stability and consistency of the process.

- Etching and cleaning

During the etching and cleaning processes, quartz boats are exposed to strong acids, strong alkalis or organic solvents. The corrosion resistance of quartz material enables it to be used for extended periods in these harsh environments without damage. Furthermore, the high purity of quartz boats ensures that the etching or cleaning effect remains unaffected by material contamination.

- Photoetching and photocuring

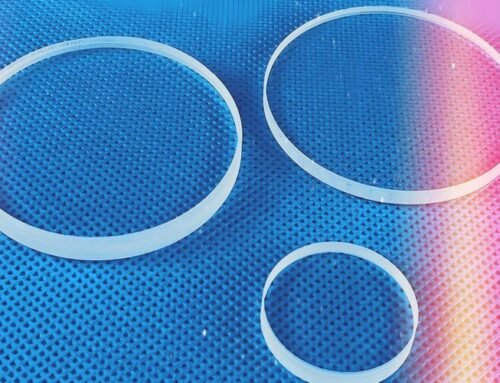

Quartz boats are widely utilized in photolithography and related processes due to their exceptional optical properties. It is able to transmit ultraviolet light effectively, ensuring uniform exposure and curing of the photoresist.

- The advantages of quartz boats

- High stability

The high purity, high-temperature resistance and chemical inertness of quartz boats make them an extremely reliable component in the semiconductor manufacturing process. It can be used for extended periods in a range of harsh environments without performance degradation, thereby ensuring the stability and consistency of the process.

- Improve production efficiency

Quartz boats are engineered to accommodate multiple wafers, thus enabling the handling of multiple wafers in a single process. This enhancement in production efficiency is a key benefit of quartz boats. Furthermore, the durability of quartz boats reduces the frequency of replacement, which in turn reduces production costs.

- Reduce the risk of pollution

The high purity of quartz material guarantees that no impurities are introduced during the manufacturing process of quartz boats, thereby significantly reducing the risk of contamination to wafers. This is of particular importance for high-precision processes in semiconductor manufacturing, as even the slightest contamination can lead to a significant decline in device performance.

- Adapt to various process requirements

The versatility of quartz boats, characterized by a wide range of designs and manufacturing processes, enables them to adapt to diverse semiconductor process requirements. Whether the requirement is for high-temperature processes, thin film deposition or etching cleaning, quartz boats provide reliable solutions.

- Conclusion

Quartz boats, as key materials in semiconductor manufacturing, play an indispensable role in processes such as wafer handling, high-temperature processing, etching, and cleaning, owing to their high purity, excellent thermal stability, chemical inertness, and low coefficient of thermal expansion. Going forward, quartz boats are expected to continue playing a significant role in the semiconductor industry, contributing to the efficiency, stability, and reliability of semiconductor manufacturing.